Composites consist of materials that have been combined to form a stronger structure than that achieved by each individual component on its own. In composites, the original components remain separate within the newly formed material, allowing them to keep their properties and pool them to create a stronger whole.

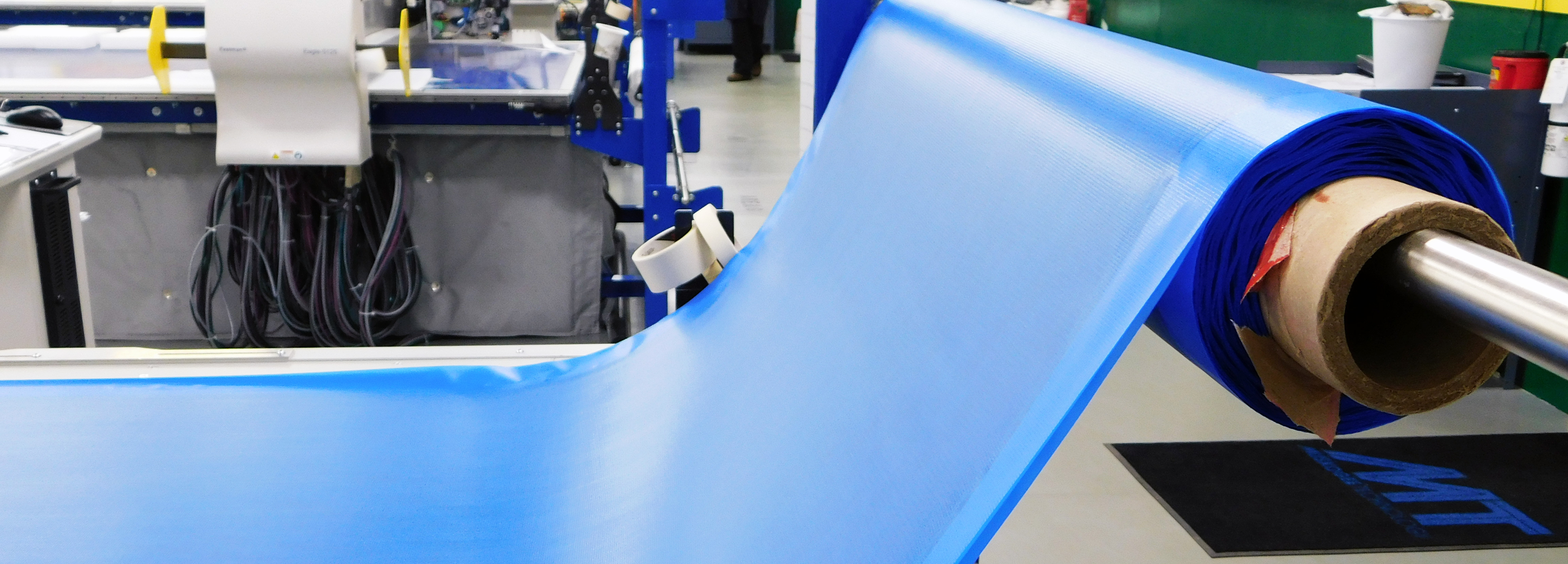

At Muskogee Technology, we offer quality composite cutting, packaging, and fiberglass buildup services. Operating from our in-house temperature, humidity, and pressure-controlled composite cleanroom, we provide quality parts for clients in the aerospace industry as well as other fields. For long-term projects, we provide sub-zero storage and finished goods freezers.

The Benefits of Composites:

Composites bring a number of advantages to finished products, such as:

- Strength: Fibers and resins help make composites stronger than materials like steel.

- Lightweight: Composites weigh less than most woods and metals, which improves fuel efficiency and allows for easier transport and installation.

- Corrosion resistance: Composites resist damage from weather and harsh chemicals, making them well-suited to applications that expose materials to toxic chemicals and other harmful environments.

- Design flexibility: Many different combinations of materials can be used to build composites, which allows for great design flexibility. Composites can be tailored to meet the specifics of your application.

- Durability: Structures made using composites have a long lifespan and require little maintenance. Many products that use composites have been in service for more than 50 years.

- Electrical insularity: Composites are electrically grounded, meaning that they do not conduct electrical charges.

- Composites bring many more significant advantages to the table. They outperform steel, another commonly used material in aerospace applications, by weighing less and offering more opportunities to modify the design.

Composites also provide a viable alternative to aluminum. Some benefits of composites over aluminum include:

- Handles tension well

- One-piece design potential

- Precise weight distribution

- High strength and flexibility

- Vibration absorption

Composites especially benefit the manufacture of aerospace parts and components. A wide range of aircraft consist primarily of composites, including:

- Commercial aircraft

- Military aircraft

- Helicopters

- Business jets

- General aviation aircraft

- Spacecraft

However, not only aerospace projects rely on composite materials. Some other industries that take advantage of composites’ strength, flexibility, and light weight include:

- Architecture

- Automotive

- Energy

- Infrastructure

- Marine

- Military

Composite Cutting

Composites have increasingly supplanted aluminum in many applications. Nearly half of the Boeing 787 consists of composites, which make it faster and more fuel efficient than previous iterations of the aircraft. Incorporating composites into the 787’s airframe reduced its weight by 20% compared with previous designs that used aluminum.

Trust Our Certified Composite Manufacturing Team Our team members bring years of experience in reverse engineering, modifying, qualifying, and manufacturing complex products to meet AS9100D and Nadcap Composites standards. We’ve successfully managed a number of large-scale, multi-year programs.

When you work with Muskogee Technology, you’ll get the full suite of our services and abilities. Some advantages we bring to every project include:

Development and maintenance of technical data packages Configuration control Development of prototypes and first articles Planning and support for production unit fabrication and testing We offer several composite services that ensure a high-quality finish, such as:

Supply chain management: We help oversee the supply chain process, which often involves volatile pricing and constrained supply. Procurement: We coordinate the manufacturing process to account for any uncertainties, and we obtain the necessary equipment and supplies ourselves. Warehousing: We can store all components used in the manufacturing process as needed. Sub-zero cold storage: For materials that require cold storage, we ensure that everything is kept at the appropriate temperature and in ideal conditions. Composite cutting and packaging: We use the appropriate tools to properly cut composites before securely packaging them for temperature-controlled transportation. Composite kitting: We thaw, cut and kit to your specifications. Request Your Composite Quote Today! Muskogee Technology builds and delivers quality composite parts for clients across the country.

If you would like to learn more about some of the advantages that switching to composites will bring to your next project, contact us or request your free quote today!